An In-Depth Exploration of Efficiency, Precision, and Innovation

Horizontal injection molding machines have emerged as critical players in the ever-evolving landscamanufacturing landscaThismprehensive exploration of the transformative impact of horizontal injection molding machine on efficiency, precision, and innovation. From their fundamental principles to the latest advancements, this article aims to provide a detailed understanding of how these machines are in the manufacturing industry.

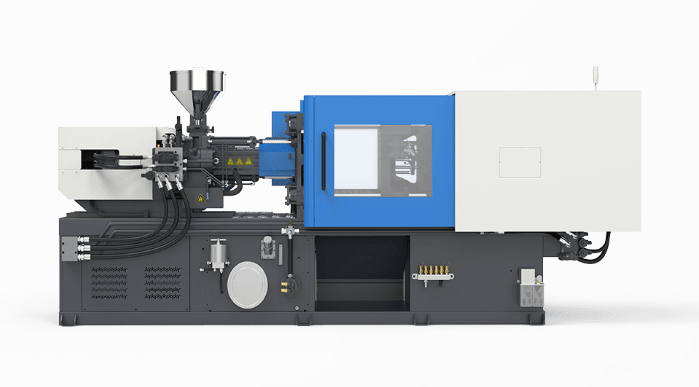

Understanding Horizontal Injection Molding Machines

Horizontal injection molding machines are machinery characterized by their horizontal orientation. This section provides an overview of the basic principles that define these machines, including their structure, functioning, and the fundamental processes involved in flat injection molding. By grasping the foundational concepts, manufacturers can appreciate the unique advantages that horizontal machines bring to the production floor.

The Advantages of Horizontal Injection Molding

- Optimal Space Utilization: One of the primary advantages of horizontal injection molding machines is their efficient use of floor space. This section explores how the horizontal configuration allows for a more compact layout, making them suitable for various environments. The optimization of space contributes to enhanced operational efficiency and cost-effectiveness.

- Versatility in Mold Design: Horizontal machines offer increased flexibility in mold design. This segment investigates how the horizontal orientation accommodates complex molds with multiple cavities, enabling manufacturers to produce intricate and diverse products. The versatility of mold design contributes to the adaptability of horizontal injection molding machines across various industries.

- Improved Accessibility for Automation: Accessibility is a critical consideration in the integration. This part examines how horizontal machines provide improved accessibility for robotic systems, facilitating seamless automation processes. The enhanced automation capabilities contribute to increased productivity and reduced labor costs.

Precision and Consistency in Horizontal Injection Molding

- Mold Clamping and Injection Unit Precision: Precision is paramount in injection molding, and horizontal machines excel in achieving precise mold clamping and injection. This section explores the factors contributing to these processes’ accuracy, including the clamping unit’s design unit technology and the control systems employed.

- Reduced Mold Wear and Tear: Horizontal injection molding machines are unminimized tears on molds. This segment investigates how the horizontal orientation distributes force evenly across the mold, reducing stress on individual components. The result is prolonged mold life, improved part quality, and decreased maintenance costs.

- Enhanced Cooling and Ejection: Cooling and ejection are critical phases in injection molding. Here, we delve into how horizontal machines optimize these processes, ensuring efficient cooling cycles and precise ejection of molded parts. The enhanced cooling and ejection mechanisms contribute to faster cycle times and increased overallivity.

Innovation and Technological Advancements

- Integrating Industry 4.0 Technologies: Horizontal injection molding machines are at the forefront of Industry 4.0 integration. This section explores how these machines leverage innovative technology, IoT (Internet of Things), and data analytics to optimize production processes. The intIntegratingry 4.0 technologies enhance predictive maintenance, real-time monitoring, and efficiency.

- Energy-Efficient Solutions: Energy efficiency is a growing concern in manufacturing. Here, we examine how modern horizontal injection molding machines incorporate energy-efficient features like driven systems and advanced control algorithms. These innovations not only reduce operational costs but also sustainable manufacturing practices.

- Material and Process Innovations: Horizontal machines continue to benefit from material and process innovations. This part explores the latest developments in materials, including advanced polymers and bioplastics, as wellandtions in injection molding processes, such as gas-assisted molding and co-injection molding. These advancements contribute to improved product quality and expanded possibilities in design and functionality.

Challenges and Considerations in Horizontal Injection Molding

- Initial Investment and Setup: While horizontal injection molding machines offer numerous advantages, their initial investment and setup costs can be significant. This section discusses considerations for manufacturers evaluating the cost-benefit analysis of adopting horizontal machines, including factors like production volume, part complexity, and long-term return on investment.

- Maintenance and Training: Maintenance and training are crucial aspects of the optimal performance of horizontal injection molding machines. Here, we explore the standard maintenance requirements and the importance of comprehensive training programs for machine operators and maintenance personnel.

- Adapting to Changing Industry Needs: The manufacturing landscape is dynamic, with changing market demands and evolving technologies. This part examines how manufacturers using horizontal injection molding machines can adapt to shifting industry needs through continuous training, staying informed about technological advancements, and maintaining flexibility in production capabilities.

Case Studies and Real-world Applications

- Automotive Industry: Explore how horizontal injection molding machines are utilized in the automotive sector for photoproduction components, interior parts, and complex assemblies.

- Consumer Goods: Investigate the applications of horizontal machines in the production of consumer goods, including household appliances, electronic components, and packaging.

- Medical Device Manufacturing: Delve into the critical role of horizontal injection molding machines in the medical device industry, where precision and consistency are paramount.

Conclusion

Horizontal injection molding machines have revolutionized the manufacturing landscape by offering various advantages, including optimal space utilization, versatility in mold design, and enhanced precision. The continuous innovation and technological advancements in these machines further underscore their significance in meeting the evolving needs of modern manufacturing. While challenges exist, the benefits and real-world applications demonstrate that horizontal injection molding machines are a cornerstone technology driving efficiency, precision, and innovation in the manufacturing sector. Manufacturers looking to stay competitive and embrace the future of injection molding would do well to explore the possibilities offered by horizontal machines.