Packaging plays a vital role in getting products to customers in prime condition while also attracting buyers, providing information, and meeting sustainability goals. As consumer preferences and business priorities continue to evolve, packaging needs to advance as well. Understanding different packaging types, materials, design considerations and emerging innovations is key for companies looking to optimize their packaging strategies.

Types of Packaging

There are three main categories of packaging:

Primary Packaging

Primary packaging directly contains the product and is the packaging most visible to consumers. It may consist of bottles, cans, wrappers, retail ready packaging (RRP) or other creative package designs tailored to the specific product. Primary packaging must balance protection, preservation, branding, sustainability, portability and cost.

Secondary Packaging

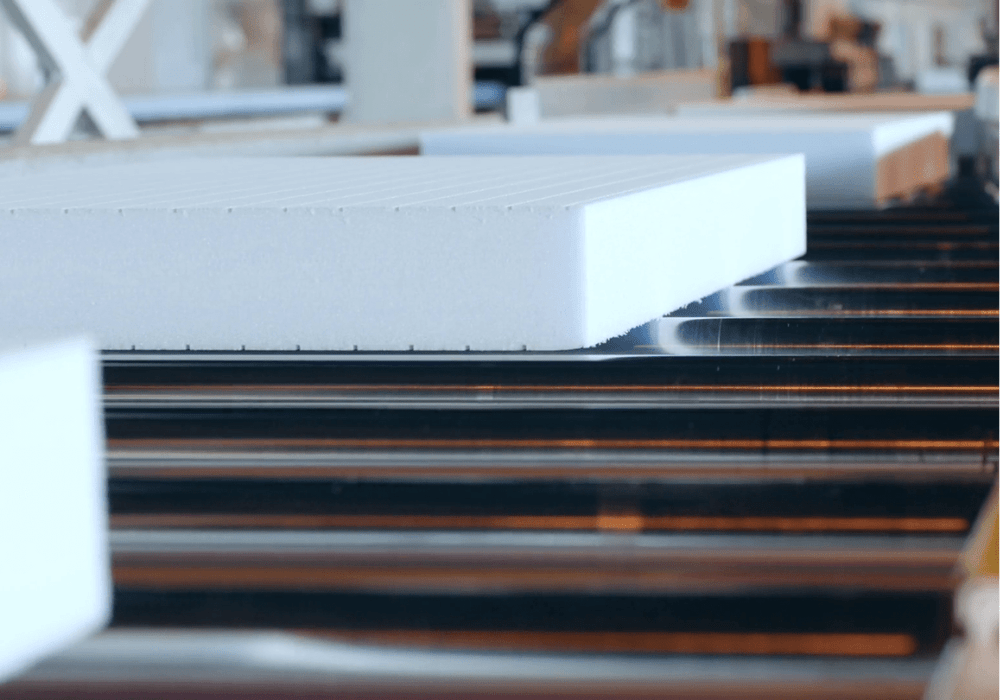

Secondary packaging contains groups of primary packages to protect them during shipping and distribution. It aids retailers in stocking shelves and moving inventory efficiently. Common forms of secondary packaging include cardboard boxes, shrink wrap and palletizing. Design focuses on stabilizing primary packaging, providing labeling information, repurposing and recycling capability.

Tertiary Packaging

Tertiary packaging consists of outer protective layers like crates, wooden boxes and reinforced corrugated boxes used in bulk cargo shipping. It enables efficient unitization to move large volumes of product efficiently via ships, trains and trucks under the rigors of multimodal transport. Design requirements prioritize ruggedness, security, storage and universal handling.

Packaging Materials

Many material options exist when selecting Packaging solutions:

Plastics

Plastics like polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and polyvinyl chloride (PVC) are common due to versatility, lightness, formability and cost-effectiveness. However, single-use plastics face environmental scrutiny, driving innovation in bioplastics, compostability and recyclability.

Paper and Cardboard

Paper and corrugated cardboard packaging provide excellent printability at low costs. Coatings and laminations improve appearance and performance. Management of sustainable forestry and fiber resources remains a priority.

Metal

Aluminum and steel packaging offer strong barrier protection, shelf appeal, recyclability and keep products cold or hot. Drawbacks center on weight and potential for leaching and corrosion. Protective inner liners help mitigate chemical reactivity concerns.

Glass

Glass excels in purity, impermeability, design aesthetics, and endless recyclability without loss of quality. Challenging aspects include weight, fragile breakability and higher costs. Lightweighting and alternative resins help reduce cost and boost performance.

Wood

Wood represents a renewable, naturally biodegradable material for both decorative and functional packaging uses. Responsible forestry certification ensures future supply. Treated wood enhances durability.

Textiles

Textile packaging appeals throughsoftness, flexibility, absorption, wearability and even reusability when designed appropriately. Blends combine positive aspects of natural and synthetic fibers.

Packaging Design Considerations

Many factors influence packaging selection and design:

Protection and Preservation

Packaging prevents damage and spoilage from moisture, oxygen, light, microbial contamination, mechanical shock, vibrations, temperature extremes and compression. Shelf life determines needed barrier properties and stabilizing solutions.

Marketing and Branding

Packaging promotes and protects brands via shapes, graphics, imagery, substrates, finishes and emotional appeal. Consumers substantially factor packaging aesthetics and originality into purchase decisions.

Sustainability

Sustainable packaging balances environmental responsibilities with performance and costs. Strategies like lightweighting, responsible material sourcing, bio-derived resins, carbon footprint reduction, recyclability and compostability signal environmental commitments to buyers.

Cost

Packaging represents a significant portion of overall product costs. Evaluating performance-to-price tradeoffs, total supply chain impacts and production efficiencies aids cost optimization.

Innovations in Packaging

Advancing technology brings new possibilities to packaging:

Smart Packaging

Intelligent packaging utilizes sensors, indicators, tracking and data capabilities integrated with communication infrastructure. Applications span freshness, temperature compliance, anti-counterfeiting, usage tracking, supply chain coordination and consumer engagement.

Biodegradable Packaging

Biodegradable materials break down through natural microbe and enzyme actions. Options like PLA, cellulose, whey protein, fiber composites, bamboo and seaweed provide renewable, compostable alternatives to conventional packaging. Limitations around costs, performance and infrastructure persist.

Light Weighting

Doing more with less material increases sustainability and reduces distribution costs. Changes to shapes, wall thicknesses, coatings and material substitutions lessen environmental footprints.

The Future of Packaging

Ongoing packaging innovations will enable smart packages offering dynamic feedback, protection, identification, tracking and consumer experiences far surpassing inert containers of the past. They will facilitate the circular economy and revolutionize retail environments. Bioplastics and composites will achieve cost and performance parity with less sustainable incumbent materials. Reusable packaging models will expand across supply chains. Packaging will act as a core business growth driver rather than passive logistics necessity. Companies proactively moving toward creative packaging solutions will gain competitive advantage as consumer values and industry standards evolve.

Conclusion

Packaging constitutes an integral bridge linking products and consumers. It speaks on behalf of brands. As sustainability concerns, digitization, global distribution and consumer preferences advance, packaging must progress in parallel. By leveraging material wisdom, strategic design principles and emerging technological capabilities, packaging will continue improving lives through successfully delivering products in an environmentally responsible manner. Companies investing in cutting edge packaging systems and taking a lifecycle view on meeting demand will lead markets going forward.

FAQs

What are the main types of product packaging?

The three primary categories are primary packaging directly enveloping a product, secondary packaging unitizing primary packages for distribution and tertiary packaging securing secondary loads for shipping.

How does packaging influence consumer purchasing choices?

Packaging aesthetics, novelty, claims, transparency to contents and inferred sustainability all sway product selection and brand loyalty.

What recent innovations show the most promise for packaging?

Smart packaging with indicators and data tracking along with biodegradable, compostable materials like PLA, cellulose and bio-derived polymers provide environmentally-friendly functionality.

How might future packaging capabilities evolve?

Packaging will increasingly act as an interactive hub offering connections to digital experiences, dynamic communications and creative retail journeys going beyond static containment.

Why should companies make packaging central to their business strategy?

Packaging remains the last communication and physical interaction with customers. As consumer values and industry norms drive toward sustainability and digitization, packaging must spearhead necessary transformations.